What Are “Rare Earths” — and Why They’re Everywhere in Modern Life

Rare earth elements (REEs) are a group of 17 metallic elements — the lanthanides, plus scandium and yttrium — that may be found in tiny amounts but have an enormous impact on technology. These elements make modern devices faster, stronger, and more efficient. They power the permanent magnets used in electric vehicle (EV) motors and wind turbines (mainly neodymium and praseodymium, with dysprosium and terbium for heat resistance). They help fiber-optic cables transmit global internet data (erbium) and bring color to TVs, LEDs, and medical imaging devices (europium, terbium).

You’ll also find them in jet engines, radar systems, satellites, and smart weapons — making REEs essential to both clean energy and national security.

From an industrial point of view, the rare earth supply chain has three main steps:

- Mining and concentrating the ore

- Separating and refining individual elements

- Manufacturing magnets (usually NdFeB or SmCo)

The real value lies in steps two and three — refining and magnet production — which are also where global bottlenecks exist. Demand is growing quickly, especially for neodymium-iron-boron (NdFeB) magnets, which are vital for EV motors and direct-drive wind turbines.

Why Rare Earths Matter for Energy and Defense

The global shift toward electrification and wind power is driving massive demand for high-performance magnets. As the number of EVs and turbines increases, so does the need for NdPr oxides and heavy rare earths like dysprosium and terbium, which help magnets stay strong even in high temperatures.

Industry experts and policy analysts predict that demand for rare earths will continue to rise across every clean energy scenario. These materials are extremely difficult to replace without sacrificing performance or efficiency.

From a defense perspective, rare earths are equally critical. They are used in precision-guided missiles, fighter jets, and radar systems — so having a stable and secure supply isn’t just economic, it’s strategic.

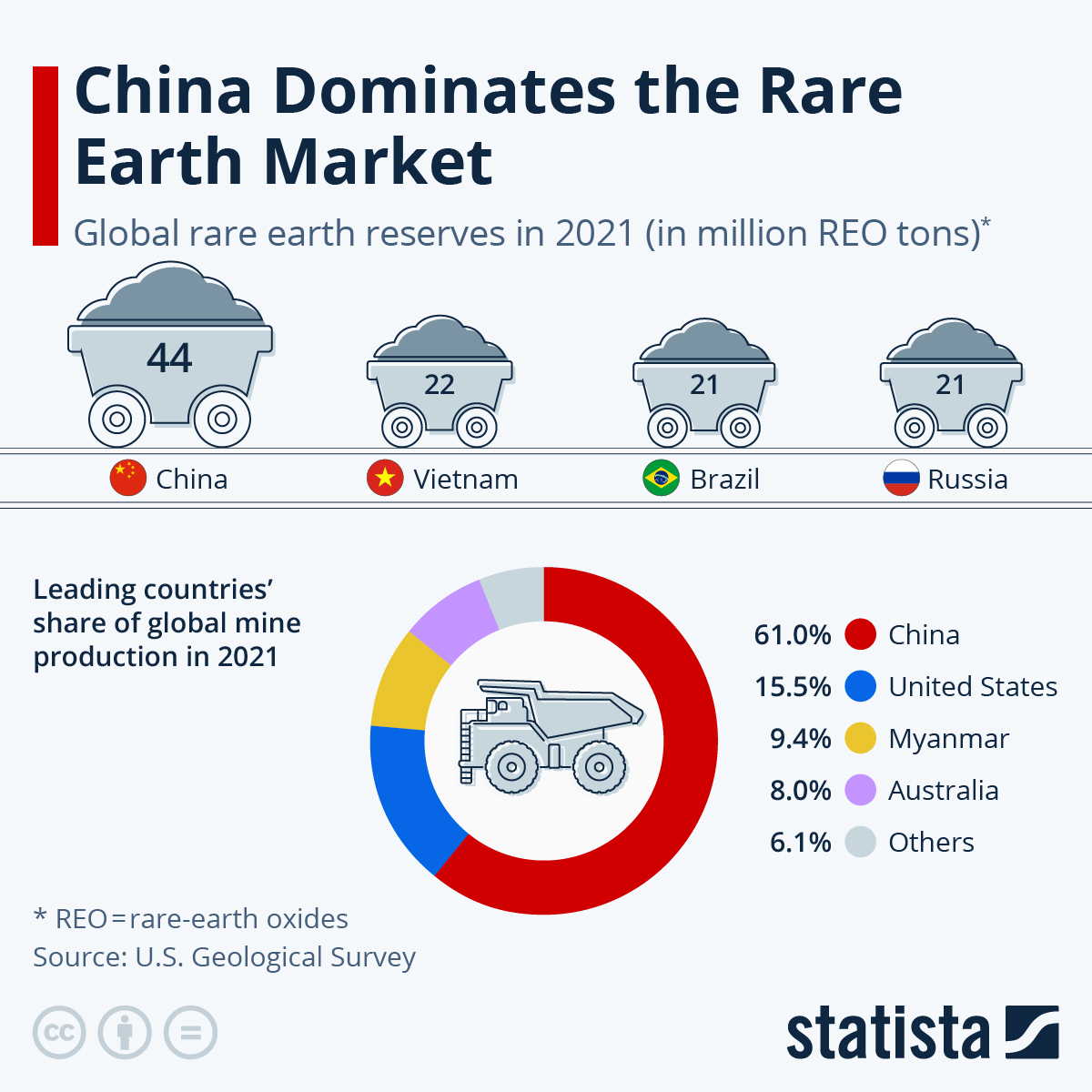

China’s Dominant Role: Mining Power, Refining Control, and Magnet Leadership

China has built near-total control over the rare-earth industry by investing heavily in it for decades. The country now dominates both the midstream (refining) and downstream (magnet-making) parts of the supply chain. Today, China produces over 90% of the world’s refined rare earths and magnets, as well as most of the mining output.

This dominance means that any policy change in China — such as new export rules — immediately impacts industries worldwide, from automakers to defense suppliers. Recent restrictions have targeted not only raw materials but also equipment, recycling technology, and buyers in sensitive sectors like defense and semiconductors.

China’s strength isn’t just about policy—it’s also geological. The Bayan Obo mine in Inner Mongolia is the largest rare-earth deposit in the world and anchors China’s processing hub in Baotou.

In contrast, the Mountain Pass mine in California is the largest source in the West, but the U.S. is still working to rebuild its refining and magnet-making capacity. Compared with China’s integrated ecosystem, the Western supply chain remains fragmented and under development.

The Hidden Cost Behind Cheap Prices: Environmental and Social Impacts

China’s early leadership in rare earths came at a high environmental cost. Refining REEs involves intense chemical processing that can generate acidic waste, fluoride-rich byproducts, and even radioactive residues if not carefully managed.

In Baotou, waste from rare-earth processing has created serious pollution and water contamination issues over the years. Cleaner and safer refining methods do exist—and are now required in many countries—but they’re expensive. This higher cost has slowed the growth of rare-earth supply chains outside China.

To build a responsible and sustainable supply chain, future projects must include strong environmental controls, water treatment, and recycling systems, so that cleaner production doesn’t simply mean shifting pollution elsewhere.

How China’s Policies Affect the World: Price Shocks, Shortages, and Redesigns

When China changes its export rules, the effects are felt instantly. Manufacturers face uncertainty, delays, and price spikes for key oxides and alloys. Some even have to redesign their motors using ferrite-based magnets or induction systems to reduce dependency.

In the past, companies that switched suppliers often returned to Chinese sources once prices stabilized — leaving the overall dependency in place.

The latest export restrictions go further by affecting foreign producers that rely on Chinese materials or tools, which has raised compliance risks and pushed global companies to look harder at diversifying their supply chains.

The Diversification Strategy: Building Supply Chains Beyond China

United States:

The Mountain Pass mine (run by MP Materials) has revived large-scale mining and refining operations. It’s now producing separated NdPr oxide and, with U.S. Department of Defense support, building domestic magnet-manufacturing facilities. These efforts aim to reduce dependence on Chinese magnets for both commercial and military needs.

Australia & Malaysia (Lynas):

Lynas Rare Earths is the biggest producer outside China. It mines at Mt. Weld, processes mixed rare-earth carbonate at Kalgoorlie, and separates final products in Malaysia. Lynas is also partnering with U.S. firms to help create a complete “mine-to-magnet” supply chain in North America.

European Union:

The EU’s Critical Raw Materials Act (CRMA) sets targets for 2030: mine 10% of its needs locally, refine 40%, and recycle 25%, while ensuring no more than 65% of any step depends on a single foreign source. Projects like Solvay’s La Rochelle facility and Estonia’s refining plants are progress signs, but Europe still faces challenges with permits, costs, and competition.

Japan:

After a major supply crisis in 2010, Japan diversified its sources through JOGMEC-backed investments, especially in Lynas. Japan also became a pioneer in magnet recycling, a strategy now being copied by the U.S. and EU.

Recycling and Circularity:

Companies like Urban Mining Co. and HyProMag are turning old magnets from motors and hard drives into new ones—a process called magnet-to-magnet recycling. It’s not a full solution, but it significantly lowers environmental impact and demand for newly mined materials.

Practical Solutions: How to Reduce Risk Without Sacrificing Performance

- Invest in bottlenecks — refining and magnet-making.

Mining alone isn’t enough. The biggest opportunities for supply resilience lie in chemical separation and magnet production. Governments and private investors need to fund facilities that can handle heavy REEs like dysprosium and terbium, which are the scarcest and most crucial for high-heat magnets. - Design products that use fewer rare earths.

Automakers and turbine manufacturers can reduce dysprosium use by improving thermal design and grain-boundary diffusion or using ferrite/induction motors where possible. This approach—called demand-thrifting—helps relieve pressure on the supply chain faster than new mines can be developed. - Make recycling the norm.

Governments should require magnet take-back programs for EVs, e-bikes, and wind turbines, and set future recycled-content goals once enough material is available. Efficient recovery systems will make recycling easier and safer. - Diversify supply geographically.

Build “friend-shored” partnerships with trusted countries—like the U.S., Australia, Canada, India, and the EU—to prevent a new single-point dependency. - Include environmental and social costs from the start.

Modern facilities must include strict water treatment, safe thorium disposal, and zero-liquid discharge systems. These measures increase upfront costs but create long-term stability, reduce local opposition, and make supply chains more sustainable.

What This Means for Businesses, Policymakers, and Students

For business leaders in automotive, clean energy, and electronics, rare earths have become a strategic issue. Companies should map where their materials—especially NdPr, Dy, and Tb—come from, develop backup supply sources, and push engineering teams to design products that use fewer of these elements.

For policymakers, the priority is clear: align funding, fast-track permitting, and support projects focused on refining and magnet-making, not just mining.

For students and engineers, this is an exciting and impactful field. It combines materials science, chemistry, magnet design, and supply-chain strategy—offering opportunities to contribute to cleaner, more secure technologies.

From Dependency to Durability

Rare earth elements aren’t actually “rare”—but responsible and reliable supply chains are. For years, the world has relied on a single country for most of its refining and magnet-making capacity. That concentration kept prices low but created environmental damage and made global supply chains fragile.

The path forward is achievable:

- Invest in refining and magnet capacity outside China,

- Design smarter, resource-efficient products, and

- Make recycling standard practice.

By taking these steps, the world can make the clean energy transition stronger, fairer, and more resilient—ensuring that the technologies powering our future rest on a truly sustainable foundation.